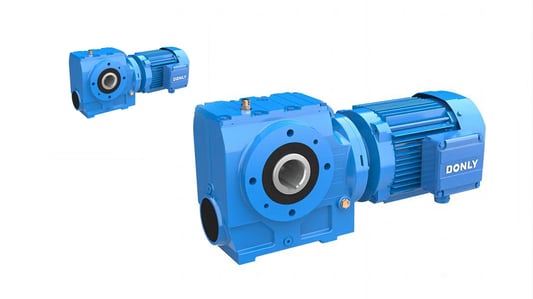

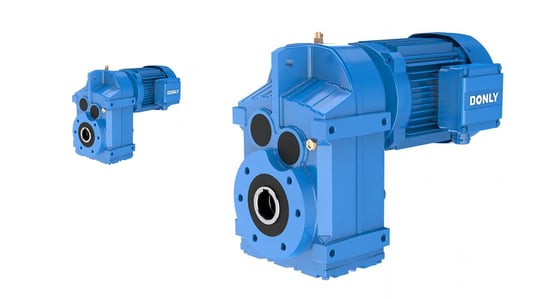

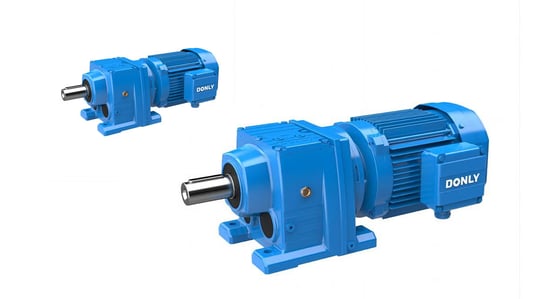

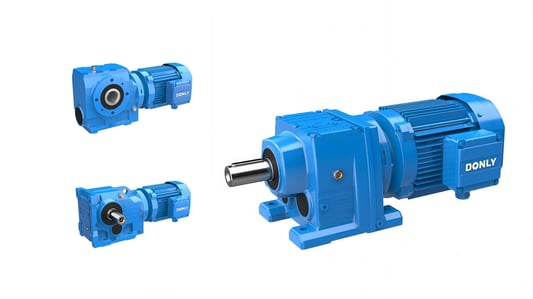

The Importance of gear boxes in MachineryGear boxes play a crucial role in machinery by regulating the speed and torque of the equipment. They are essential components that help machines operate efficiently and effectively. Without gear boxes, the movement of machinery would be erratic and unreliable.Types of Gear BoxesThere are various types of gear boxes available, including spur gear boxes, helical gear boxes, bevel gear boxes, and planetary gear boxes. Each type serves a specific purpose and is designed to meet different performance requirements. Understanding the differences between these types can help you choose the right gear box for your machinery.Benefits of Using Gear BoxesGear boxes offer several benefits, such as increased power output, precise control of speed and torque, improved efficiency, and reduced wear and tear on machinery. By incorporating gear boxes into your equipment, you can enhance performance and prolong the lifespan of your machines.Factors to Consider When Selecting Gear BoxesWhen selecting gear boxes for your machinery, consider factors such as the required torque and speed, the environment in which the equipment will operate, maintenance requirements, and budget constraints. By carefully evaluating these factors, you can choose gear boxes that are best suited for your specific needs.Common Issues With Gear BoxesGear boxes may encounter common issues such as overheating, lubrication problems, vibration, noise, and gear wear. These issues can impact the performance of the machinery and lead to costly repairs if not addressed promptly. Regular maintenance and timely repairs can help prevent these problems.Importance of Proper Gear Box MaintenanceProper maintenance of gear boxes is essential to ensure the longevity and efficiency of machinery. Regularly inspecting gear boxes for signs of wear and tear, monitoring lubrication levels, and addressing any issues promptly can help prevent breakdowns and costly repairs. A well-maintained gear box can significantly extend the lifespan of your equipment.Choosing the Right Gear Box for Your ApplicationWhen choosing a gear box for your application, consider factors such as the required gear ratio, input and output speed, available space for installation, and environmental conditions. Consulting with a professional engineer or gear box specialist can help you determine the most suitable gear box for your specific requirements.Latest Technological Advancements in Gear Box DesignAdvancements in technology have led to the development of innovative gear box designs that offer improved efficiency, higher torque capacity, and reduced noise levels. Features such as integrated sensors, advanced lubrication systems, and digital monitoring capabilities have revolutionized the gear box industry, making modern gear boxes more reliable and performance-driven.Applications of Gear Boxes in Various IndustriesGear boxes find applications in a wide range of industries, including automotive, aerospace, manufacturing, and robotics. From controlling the speed of conveyor belts to powering heavy machinery, gear boxes play a vital role in the operation of various equipment. Understanding the diverse applications of gear boxes can help you appreciate their significance in different industries.ConclusionIn conclusion, gear boxes are indispensable components that form the backbone of machinery across industries. Understanding the importance of gear boxes, selecting the right type for your application, and maintaining them properly can enhance the performance and longevity of your equipment. Stay informed about the latest advancements in gear box technology to ensure that your machinery remains efficient and reliable.Quote Inquirycontact us