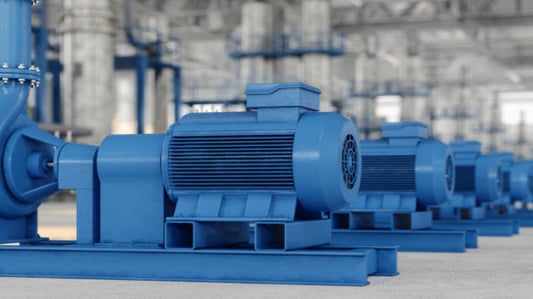

Wide Range of Heavy-duty Electric Motors Available When it comes to manufacturing equipment, having a reliable heavy-duty electric motor is crucial. That's why it's important to choose a supplier that offers a wide range of options to meet your specific needs. From high horsepower motors to energy-efficient models, a top heavy-duty electric motor supplier will have everything you need to keep your operations running smoothly.Custom Solutions for Your Manufacturing Equipment Every manufacturing operation is unique, and sometimes off-the-shelf motors just won't cut it. That's why a reputable heavy-duty electric motor supplier will offer custom solutions tailored to your exact specifications. Whether you need a motor with a specific voltage rating, speed, or special mounting requirements, a reliable supplier will work with you to design a motor that fits your needs perfectly.Exceptional Quality and Durability When it comes to manufacturing equipment, durability is key. A top heavy-duty electric motor supplier will offer products that are built to last, with high-quality materials and expert craftsmanship. These motors are designed to withstand the rigors of heavy-duty industrial use, ensuring that your equipment runs smoothly and reliably for years to come.Expert Technical Support and Service Choosing the right heavy-duty electric motor for your manufacturing equipment can be a complex process. That's why it's important to work with a supplier that offers expert technical support and service. From helping you select the right motor for your application to providing troubleshooting assistance if issues arise, a reliable supplier will be there to support you every step of the way.Competitive Pricing to Fit Your Budget Running a manufacturing operation is expensive, and every dollar counts. A top heavy-duty electric motor supplier will offer competitive pricing on their products, ensuring that you get the quality you need at a price that fits your budget. Whether you're a small operation or a large industrial facility, a reputable supplier will have options to meet your financial constraints.Fast and Reliable Delivery Options Downtime is the enemy of any manufacturing operation, so when you need a new heavy-duty electric motor, you need it fast. A trustworthy supplier will offer fast and reliable delivery options to minimize your downtime and keep your operations running smoothly. Whether you need a motor shipped across the country or across town, a reliable supplier will get it to you quickly.Industry-Leading Warranty Coverage When you invest in a heavy-duty electric motor for your manufacturing equipment, you want to know that your purchase is protected. A top supplier will offer industry-leading warranty coverage on their products, giving you peace of mind knowing that your investment is secure. Whether you need repairs, replacements, or just some expert advice, a reputable supplier will be there to help.Environmentally Friendly Options Available As sustainability becomes a bigger priority for manufacturing operations, it's important to choose electric motors that are environmentally friendly. A leading heavy-duty electric motor supplier will offer energy-efficient options that help reduce your carbon footprint and lower your operating costs. By choosing a supplier that prioritizes sustainability, you can do your part to protect the planet while keeping your operations efficient.Global Reach for International Operations If your manufacturing operations span the globe, it's important to choose a heavy-duty electric motor supplier with a global reach. A top supplier will have the infrastructure and resources to serve international customers, ensuring that you can get the motors you need no matter where your operations are located. Whether you need motors for a plant in the US, Europe, or Asia, a reputable supplier will have you covered.Continuous Innovation and Product Development The world of manufacturing is constantly evolving, and it's important to choose a heavy-duty electric motor supplier that keeps up with the latest technological advances. A leading supplier will invest in continuous innovation and product development, ensuring that you have access to the most cutting-edge motor technology on the market. By choosing a supplier that prioritizes innovation, you can stay ahead of the competition and keep your operations running smoothly. Quote InquiryContact us!