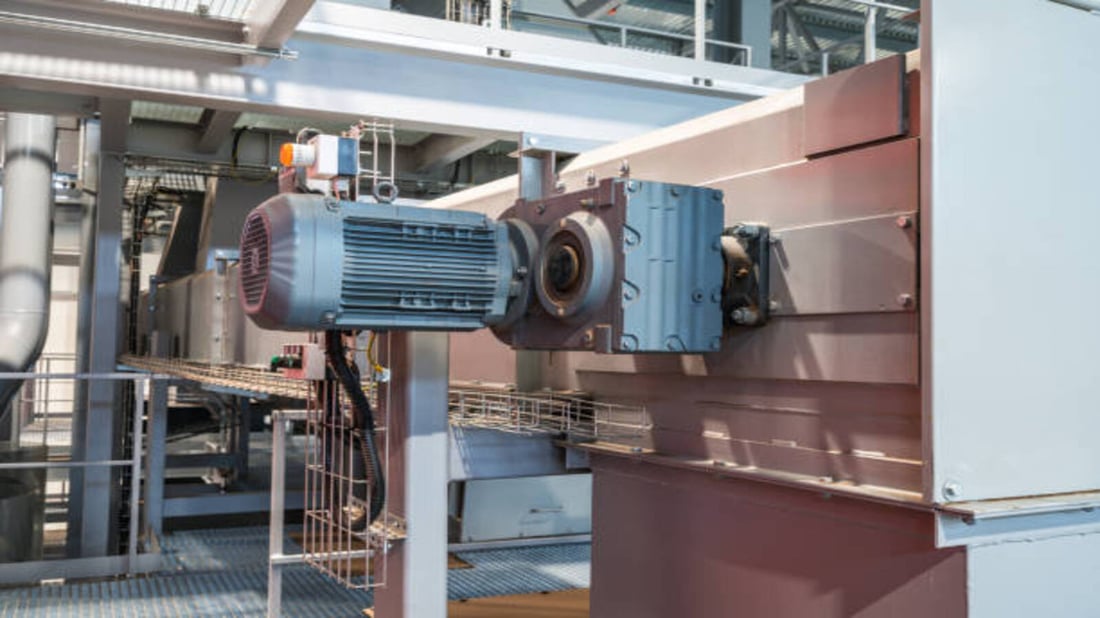

The Importance of High-Efficiency Electric Motors in Industrial Settings

Electric motors are essential components in various industrial applications, ranging from manufacturing plants to transportation systems. High-efficiency electric motors play a crucial role in reducing energy consumption and increasing overall operational efficiency.

Choosing the Right Manufacturer for High-Efficiency Electric Motors

When selecting a manufacturer for high-efficiency electric motors, it is essential to consider factors such as product quality, reliability, and energy efficiency. Look for a manufacturer with a proven track record of producing top-tier electric motors for industrial use.

Benefits of Using High-Efficiency Electric Motors

High-efficiency electric motors offer several advantages, including lower energy costs, reduced maintenance requirements, and improved performance. These motors can help industrial facilities achieve their sustainability goals while enhancing productivity.

Technology Innovation in High-Efficiency Electric Motors

Manufacturers of high-efficiency electric motors are constantly innovating to improve motor efficiency and performance. New technologies, such as advanced materials and smart motor controls, are being integrated into electric motor designs to maximize energy savings and reliability.

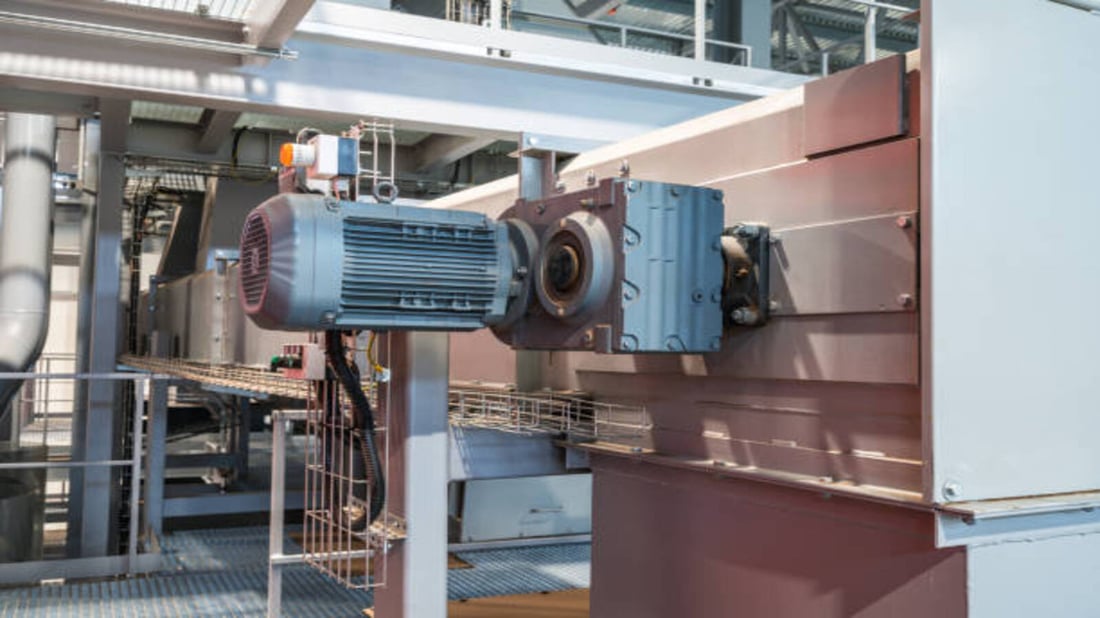

Customization Options for Industrial Electric Motors

Many high-efficiency electric motor manufacturers offer customization options to meet the specific needs of industrial customers. From motor size and speed to voltage and mounting configurations, these manufacturers can tailor electric motors to fit unique industrial applications.

Environmental Impact of High-Efficiency Electric Motors

Using high-efficiency electric motors in industrial settings can significantly reduce carbon emissions and overall environmental impact. By switching to energy-efficient motors, industrial facilities can contribute to a greener and more sustainable future.

Regulatory Standards for High-Efficiency Electric Motors

There are regulatory standards and certifications that high-efficiency electric motor manufacturers must adhere to. These standards ensure that electric motors meet strict energy efficiency requirements and quality control measures set forth by regulatory bodies.

Cost Considerations for High-Efficiency Electric Motors

While high-efficiency electric motors may have a higher upfront cost compared to standard motors, the long-term savings on energy bills and maintenance expenses outweigh the initial investment. Industrial facilities can benefit financially from the energy efficiency of these motors.

Energy Savings Potential with High-Efficiency Electric Motors

Industrial facilities can achieve significant energy savings by replacing old and inefficient electric motors with high-efficiency models. The energy savings potential of these motors can lead to reduced operating costs and increased profitability for industrial businesses.

Future Trends in High-Efficiency Electric Motor Manufacturing

The future of high-efficiency electric motor manufacturing is promising, with ongoing advancements in motor design and technology. As the demand for energy-efficient solutions continues to grow, manufacturers will continue to innovate and develop cutting-edge electric motor solutions for industrial use.

Quote Inquiry

Contact us!