Introduction to Low-Cost Electric Motor Manufacturing

The demand for electric motors has been on the rise in various industries due to their efficiency and eco-friendliness. As a result, the need for low-cost electric motor manufacturers for large-scale production is crucial. Let's explore the different aspects of this industry and how manufacturers are catering to this demand.

Benefits of Using Low-Cost Electric Motors

Low-cost electric motors are not only economical but also offer energy efficiency and long-term savings. They are ideal for large-scale production, as they can help companies reduce operational costs and improve their overall profitability. Manufacturers are focusing on enhancing the performance and reliability of these motors to meet the diverse needs of industrial applications.

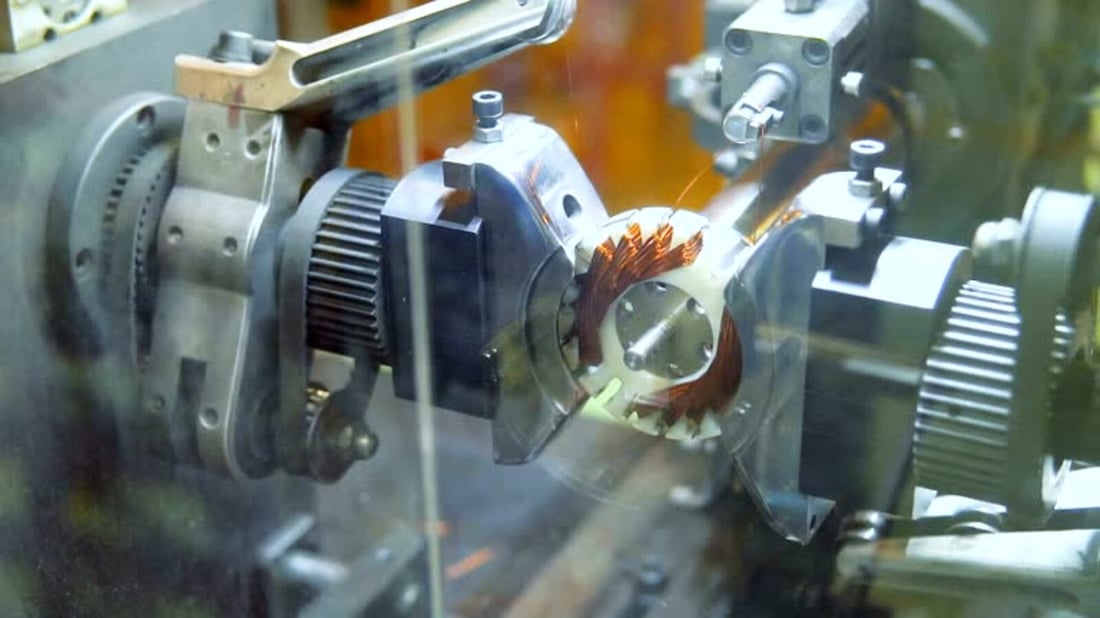

Technological Innovations in Electric Motor Manufacturing

Technological advancements have revolutionized the way electric motors are designed and produced. Manufacturers are employing innovative techniques such as automation, AI, and 3D printing to streamline production processes and reduce costs. These technologies are enabling companies to achieve economies of scale and meet the growing demand for electric motors in various industries.

Factors to Consider When Choosing a Low-Cost Electric Motor Manufacturer

When selecting a

Low-cost electric motor manufacturer for large-scale production, it is essential to consider factors such as quality, reliability, lead time, and cost-effectiveness. Companies should partner with manufacturers who have a track record of delivering high-quality products on time and within budget. By conducting thorough research and due diligence, companies can ensure that they are getting the best value for their investment.

Market Trends in Electric Motor Manufacturing

The electric motor manufacturing industry is witnessing several trends, including the shift towards sustainable and energy-efficient solutions. Manufacturers are increasingly focusing on developing eco-friendly electric motors that comply with regulatory standards and address environmental concerns. By staying abreast of market trends, companies can capitalize on emerging opportunities and stay ahead of the competition.

Sustainability Initiatives in Electric Motor Production

Sustainability has become a key focus area for electric motor manufacturers, as companies strive to reduce their carbon footprint and adopt green manufacturing practices. By incorporating sustainable materials and processes into production, manufacturers can minimize waste, conserve resources, and promote environmental responsibility. These initiatives not only benefit the planet but also enhance the reputation of manufacturers in the industry.

Challenges Faced by Low-Cost Electric Motor Manufacturers

Despite the numerous benefits of low-cost electric motors, manufacturers face challenges such as market volatility, supply chain disruptions, and increasing competition. To overcome these challenges, manufacturers must invest in research and development, leverage strategic partnerships, and optimize their production processes. By addressing these challenges proactively, manufacturers can ensure their long-term success in the industry.

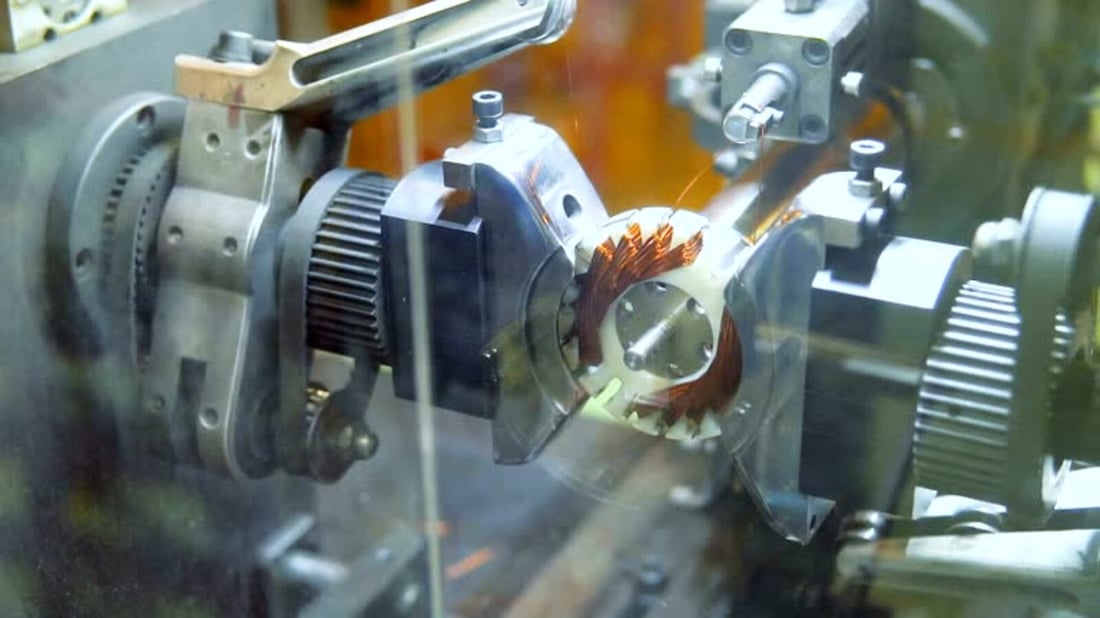

Quality Control Measures in Electric Motor Manufacturing

Quality control is paramount in electric motor manufacturing to ensure that products meet industry standards and customer expectations. Manufacturers employ rigorous testing and inspection protocols throughout the production process to detect defects, identify potential issues, and maintain product quality. By implementing robust quality control measures, manufacturers can deliver reliable and high-performance electric motors for large-scale production.

Future Prospects for Low-Cost Electric Motor Manufacturers

The future looks promising for low-cost electric motor manufacturers, as the demand for electric motors continues to grow across industries. Manufacturers are investing in research and development to enhance the efficiency, durability, and performance of electric motors, catering to the evolving needs of customers. By embracing innovation and sustainability, manufacturers can position themselves as leaders in the electric motor industry and drive growth in large-scale production.

Conclusion

In conclusion, the market for low-cost electric motor manufacturers for large-scale production is dynamic and evolving, driven by technological advancements, market trends, and sustainability initiatives. Companies looking to invest in electric motors should carefully consider factors such as quality, cost, and reliability when choosing a manufacturer. By partnering with trusted manufacturers and staying informed about industry developments, companies can leverage the benefits of low-cost electric motors and drive success in their operations.

Quote Inquiry

Contact us!