The Basics of precision gear reducer for servo motors

Precision gear reducer for servo motors is a type of mechanical component that is specially designed to reduce the speed of servo motors. This type of reducer has become increasingly popular in various industrial applications, mainly for providing torque multiplication and enhanced precision.

The Advantages of Precision Gear Reducers for Servo Motors

Precision gear reducers for servo motors have numerous benefits, including:

- Increased precision

- Enhanced durability

- Improved power transmission

- Higher torque capacity

- Reduced noise and vibration

The Working Principle of Precision Gear Reducer for Servo Motors

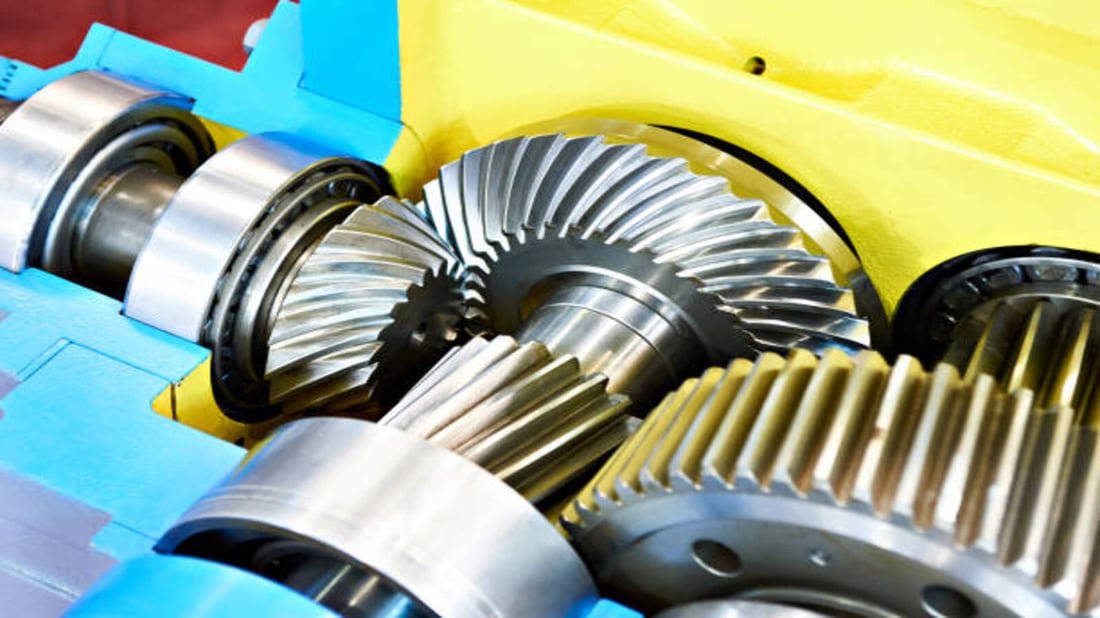

The working principle of a precision gear reducer for servo motors is simple. It uses a series of gears to reduce the speed of the servo motor output shaft while increasing torque. Each gear is designed with precision tolerances to ensure that the output speed and torque are accurate and reliable.

The Types of Precision Gear Reducers for Servo Motors

There are various types of precision gear reducers for servo motors, including:

- Planetary gear reducers

- Helical gear reducers

- Worm gear reducers

- Bevel gear reducers

The Applications of Precision Gear Reducers for Servo Motors

Precision gear reducers for servo motors are widely used in various industrial applications, including:

- Robotics

- CNC machines

- Packaging machinery

- Printing presses

- Conveyors

The Importance of Choosing the Right Precision Gear Reducer for Servo Motors

Choosing the right precision gear reducer is crucial to ensure that the servo motor operates efficiently and reliably. Selecting the wrong reducer can cause the motor to overheat, reduce the motor's lifespan, and affect the precision of the output.

The Factors to Consider When Choosing a Precision Gear Reducer for Servo Motors

When selecting a precision gear reducer for servo motors, the following factors should be considered:

- The required output torque and speed

- The environmental conditions

- The level of precision required

- The available space

- The cost of the reducer

The Benefits of Choosing a High-Quality Precision Gear Reducer

Choosing a high-quality precision gear reducer has numerous benefits, including:

- Increased durability and lifespan

- Enhanced precision and accuracy

- Reduced maintenance costs

- Improved efficiency and productivity

- Increased return on investment (ROI)

The Maintenance Requirements of Precision Gear Reducers for Servo Motors

Proper maintenance is crucial to ensure that precision gear reducers for servo motors operate efficiently and reliably. The maintenance requirements may vary depending on the type of reducer and the application. However, in general, maintenance should include regular inspection, lubrication, and cleaning.

The Conclusion

Precision gear reducers for servo motors play a vital role in various industrial applications, mainly for providing torque multiplication and enhanced precision. Choosing the right precision gear reducer is crucial to ensure that the servo motor operates efficiently and reliably.