How to Diagnose Gearbox Issues in Industrial Machinery

Industrial machinery relies heavily on functioning gearboxes for smooth operations. These gearboxes control the speed and torque of machines, allowing for efficient production. However, gearbox issues can lead to costly downtime and repairs. In this article, we’ll explore how to diagnose gearbox issues in industrial machinery and keep your operations running smoothly.

1. Abnormal Noises

If you hear a rattling, grinding, or whining noise coming from the gearbox, it could be a sign of an issue. These noises can indicate worn gears, bearings, or improper lubrication.

2. Vibration

Vibration can also be an indication of gearbox problems. If you notice excessive vibration, it could be due to misalignment or worn gear teeth.

3. Oil Analysis

Analyze the oil in the gearbox for signs of contamination, dirt, or metal shavings. This can help identify potential problems and determine if a gearbox rebuild is necessary.

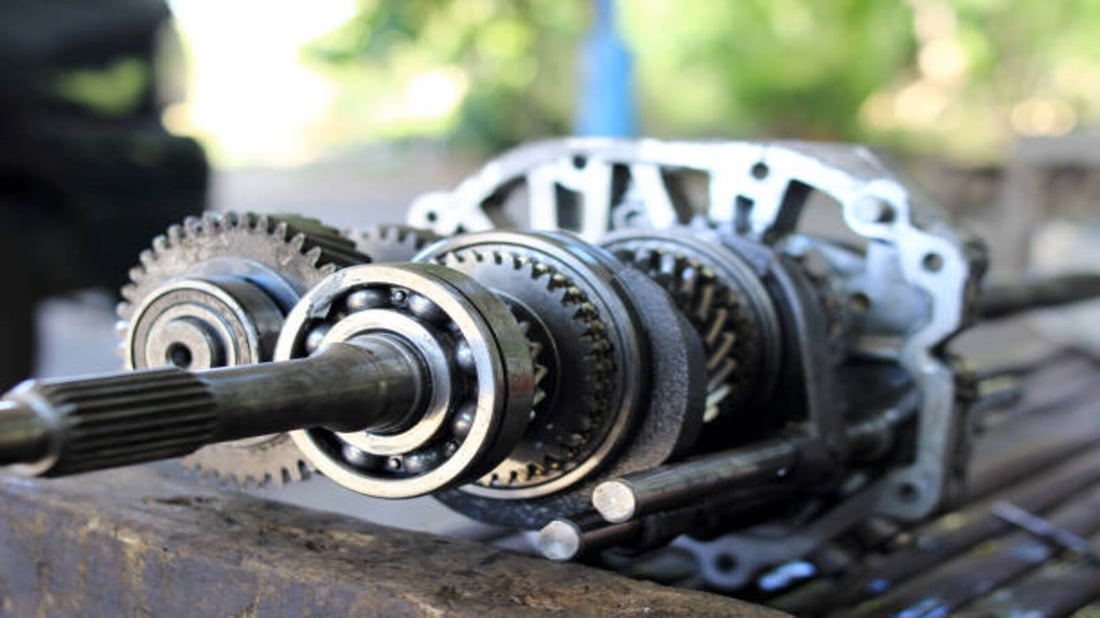

4. Visual Inspection

Perform a visual inspection of the gearbox components, such as gearing, bearings, shafts, and oil seals. Look for wear, cracks, or other signs of damage.

5. Overheating

Overheating can be a major issue in gearboxes. Monitor the temperature and check if the cooling system is functioning properly. Excess heat can lead to premature wear, gear failure, and damage to other components.

6. Acceleration Issues

If your machinery experiences acceleration issues or difficulty starting, it could be due to gearbox problems. This can be caused by worn gears, insufficient lubrication, or other issues.

7. Unusual Smells

If you detect a burning smell or other unusual odors coming from the gearbox, it could be a sign of overheating or damage to the components.

8. Input and Output Issues

A gearbox problem can cause issues with the input and output of power. This can result in machinery not functioning properly or a loss of power.

9. Load Capacity

Check the gearbox load capacity to ensure it’s not being overloaded or underutilized. Overloading can lead to damage and premature wear, while underutilization can cause lubrication issues and other problems.

10. Historical Data

Maintain detailed records of your gearbox maintenance, repairs, and performance history. This can help spot trends and identify potential issues before they become major problems.

Related potential long-tail SEO keywords:

- Industrial gearbox problems and solutions

- How to identify gearbox problems in manufacturing equipment

- Common gearbox issues in production machinery

- Preventative maintenance for industrial gearbox systems

- Ensuring optimal gearbox performance in heavy machinery