Planetary gear reducers are increasingly being used in robotics since they offer high efficiency, accuracy, and compactness in power transmission. Just as the name suggests, planetary reducers consist of several gears that revolve around a central gear "sun" to reduce the speed while increasing torque. This article provides an in-depth look at the benefits of planetary gear reducers in robotics.

2. The Advantages of Planetary Gear Reducers for Robotics

Planetary gear reducers offer several advantages over other types of reducers when used in robotics. They have a high torque density and can handle high radial loads, which is essential in robotics applications, especially for robot arms and legs. What's more, their compact size and high efficiency enable them to integrate with different types of motors.

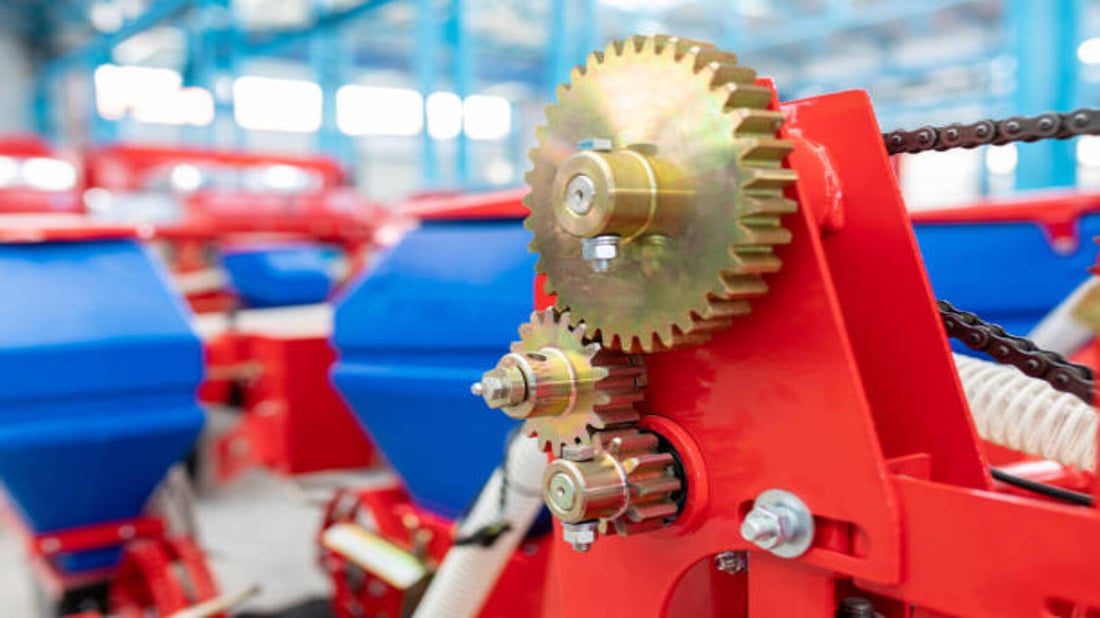

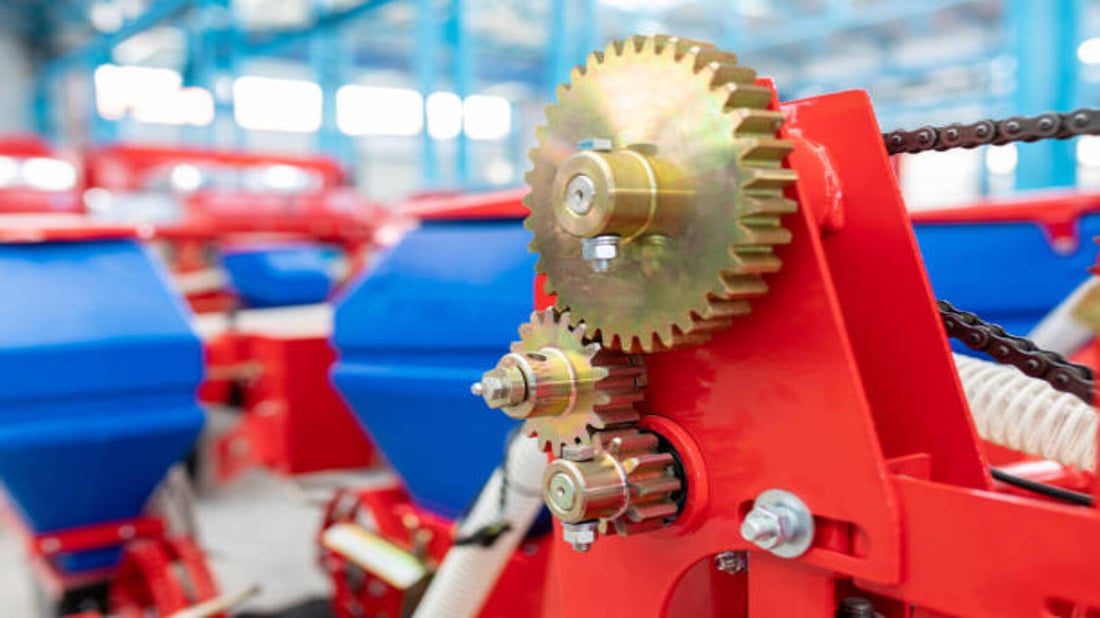

3. The Components of Planetary Gear Reducer for Robotics

Planetary gear reducers consist of several components, including the sun gear, planet gears, planet carrier, and ring gear. The sun gear is the central gear, while the planet gears revolve around it. The planet carrier keeps the planet gears in place, while the ring gear is the external gear that meshes with the planet gears. All these components work together to reduce speed while increasing torque.

4. How Planetary Gear Reducer Enhances Speed Control

Speed control is crucial in robotics applications. Planetary gear reducers offer precise control of speed, making it possible to regulate robot speed and torque. The combination of gears in the planetary system enables the input speed to be adjusted for the desired output speed. This makes it possible for robot control to coincide with application needs.

5. The Benefits of Compact Size Planetary Gear Reducer for Robotics

Planetary gear reducers are designed to be compact, which makes them an ideal choice for robotics applications. They are smaller and weigh less than traditional reducers, making them easier to integrate into robotic systems. This is crucial since the weight and size of a robot can affect its mobility.

6. Planetary Gear Reducer and Precision Robotics

Robotics applications often require precision, and planetary gear reducers provide precise positioning, reverse direction, and motion control. This is possible since the gears make precise contact and are designed to minimize backlash, which is the clearance between the teeth of the gears.

7. The Importance of Planetary Gear Reducer Durability in Robotics

In robotics, the components used must be strong and durable enough to withstand the high forces and stresses that robots can exert. Planetary gear reducers are made of high-strength materials and are designed for heavy-duty applications, which makes them ideal for use in robotics applications.

8. Planetary Gear Reducer and Energy Efficiency in Robotics

When compared to other speed reducers, planetary gear reducers offer higher efficiency, which means less energy is wasted. This is because planetary reducers can support more load while using less energy. As a result, they are ideal for robotic applications where power conservation is necessary to prolong the robot's battery life.

9. Planetary Gear Reducers and Cost-effectiveness in Robotics

Planetary gear reducers are cost-effective, making them a popular choice for robotics applications. The compact size of planetary gear reducers translates into reduced material costs and lower maintenance costs due to their high durability and efficiency.

10. Conclusion

Planetary gear reducers offer various benefits to robotics applications. They are reliable, durable, compact, and efficient. These features make them an ideal choice for robotics systems that require precision, high torque density, speed control, reliability, and cost-effectiveness.

planetary gear reducer for robotics, robot speed and torque, components for planetary gear reducer, energy efficiency in robotics

How Planetary Gear Reducer Enhances Robotics Performance

Learn how planetary gear reducer for robotics improves robot speed and torque, its components, and energy efficiency.

Quote Inquiry

Contact us!