Introduction to Gear Motors

Gear motors are commonly used in various machines and applications, from industrial machinery to household appliances. These motors are used to convert electrical energy into mechanical energy, which is then used to power different types of equipment. If you are new to gear motors and want to learn more about how they work, then keep reading.

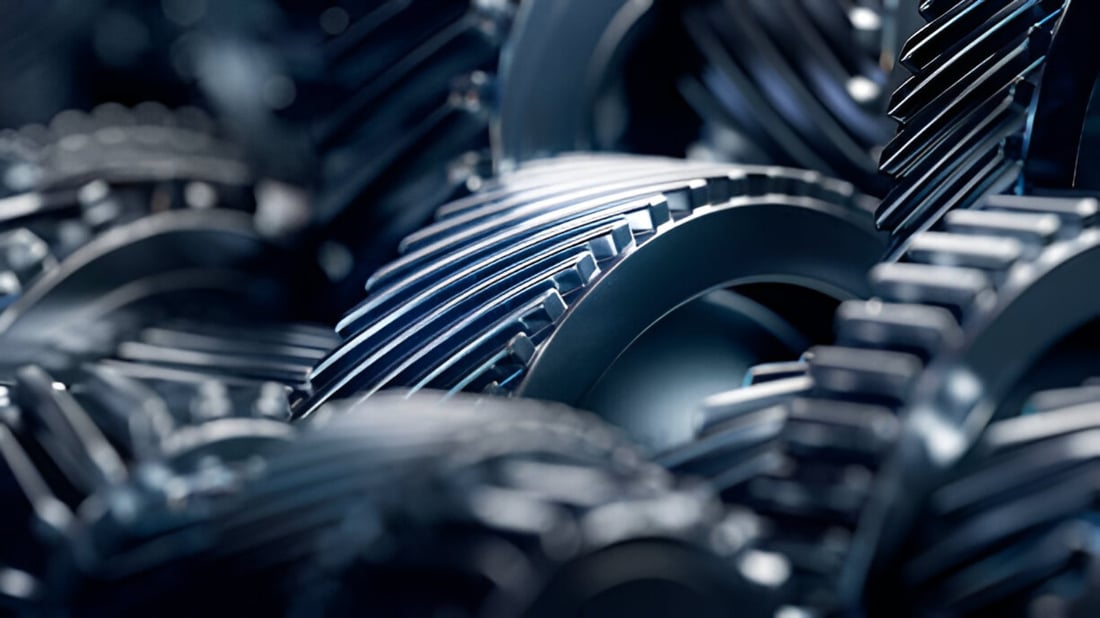

What are Gear Motors?

A gear motor is a type of electric motor that uses gears to reduce the speed of the motor while increasing the torque. The gears help to control the rotational speed and force of the motor, ensuring that it can handle heavy loads and provide a consistent level of power output.

Types of Gear Motors

There are different types of gear motors available, including DC gear motors, AC gear motors, and planetary gear motors. DC gear motors are commonly used in robotics, while AC gear motors are often used in industrial machinery. Planetary gear motors are ideal for high-torque applications, such as in drilling machines.

How Gear Motors Work

Gear motors work by using a combination of gears and a motor to drive the output shaft. The motor is connected to one of the gears, which then turns the other gears in the system, increasing the torque and reducing the speed. The output shaft is then connected to the final gear, which provides the power output.

Components of Gear Motors

Gear motors consist of four main components, which include the motor, gears, output shaft, and housing. The motor is the primary part of the gear motor, while the gears help to control the speed and force of the motor. The output shaft is responsible for transmitting the power output, while the housing helps to protect the internal components.

Gear Ratio

Gear ratio is an important factor to consider when it comes to gear motors. It refers to the ratio between the number of teeth on the driving gear and the number of teeth on the driven gear. A higher gear ratio means that the output speed will be slower, but the torque will be higher, while a lower gear ratio means that the output speed will be faster, but the torque will be lower.

Advantages of Gear Motors

Gear motors offer several advantages, such as high torque output, energy efficiency, and durability. They are also compact in size, making them ideal for use in tight spaces. Gear motors can also operate at varying speeds and with varying loads, making them versatile and suitable for different applications.

Applications of Gear Motors

Gear motors are commonly used in various applications, such as in conveyor systems, power tools, robotics, and household appliances. They are also used in industrial machinery, such as drilling machines, cranes, and lifts. Gear motors are essential for any application that requires a reliable and consistent power source.

Care and Maintenance of Gear Motors

To ensure that gear motors continue to work efficiently, they require regular maintenance and care. This includes proper lubrication of the gears, regular cleaning of the internal components, and checking for any signs of damage or wear. It is also important to follow the manufacturer's guidelines for maintenance.

Conclusion

Gear motors are an essential component in many machines and applications. They offer high torque output, energy efficiency, and durability. By understanding how gear motors work and their various components and applications, you can make informed decisions about their use in your own projects or applications.