How Gear Motors Are Revolutionizing Robotics: The Future of Automation

The latest advancements in robotics have boosted the production efficiency of many industries. Over the years, technological advancements have made it possible to increase the precision and speed of automated systems. However, one of the biggest driving forces behind these improvements is the gear motor. Gear motors are changing the way that robotics are being used to revolutionize the manufacturing industry. This article explores how gear motors are driving the automation revolution.

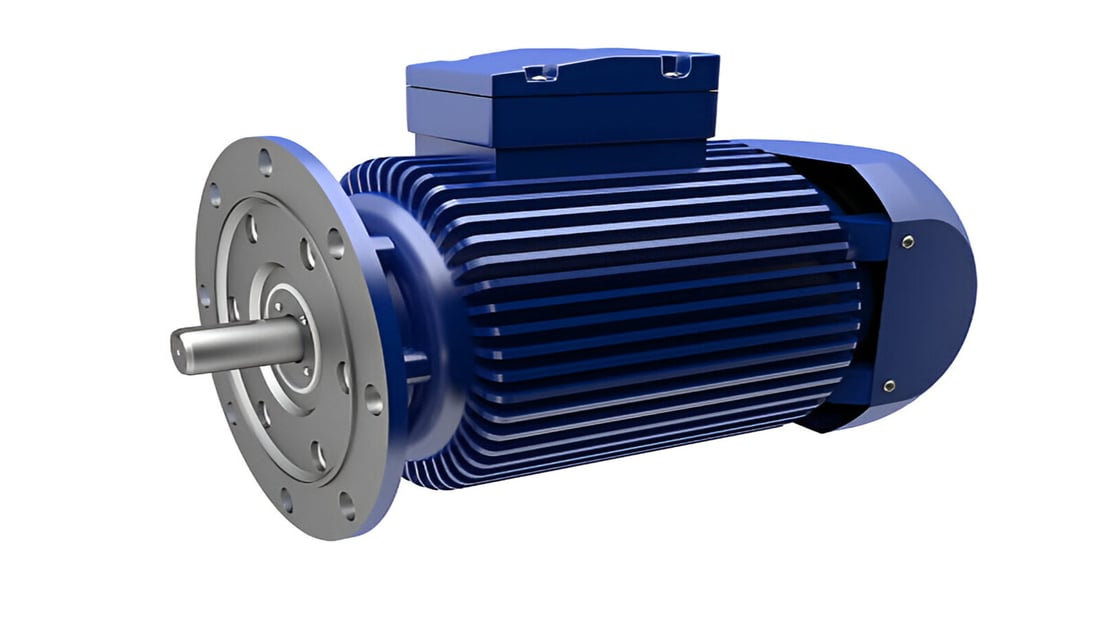

1. What are gear motors?

Gear motors are electric motors that incorporate a set of gears to reduce the speed of the motor and to increase its torque. These motors also offer a higher level of precision compared to other motors. This is especially important in robotics where accuracy is key. The use of gear motors has allowed robotic systems to perform more complex tasks that previously were not possible.

2. Benefits of Using Gear Motors in Robotics

Gear motors provide several benefits to the robotics industry. Firstly, they offer high levels of reliability and durability. They are designed to handle high workloads and to operate for long periods of time without failure. Secondly, they offer improved efficiency and energy savings. By reducing the motor's speed and increasing torque, the motor can operate at lower speeds, requiring less energy. Finally, they offer high levels of adaptability and flexibility, allowing engineers to adjust the motor to meet specific application requirements.

3. Types of Gear Motors

There are various types of gear motors, each suitable for different applications. The most common types are worm gear motors and planetary gear motors. Worm gear motors are used in applications that require high ratios of reduction and low noise level. Planetary gear motors are used in applications that require high accuracy and precision.

4. Applications of Gear Motors in Robotics

Gear motors are being widely used in the robotics industry, especially in automation. They are commonly used in packaging equipment, assembly lines, conveyor belts, and other manufacturing processes. They are also used in the automotive industry, for example, in manufacturing and welding robots. The use of gear motors in robotic systems has significantly increased the accuracy and speed of these systems.

5. Impact on Robotics Industry

The use of gear motors has greatly impacted the robotics industry. They have resulted in an increase in production efficiency, accuracy and precision. Gear motors have enabled robotic systems to perform complex tasks that were previously not possible. The use of gear motors has also made robotics systems more affordable, as they reduce the need for complex control systems. As a result, gear motors have become an essential part of robotics technology.

6. Advancements in Gear Motor Technology

With the advancements in gear motor technology, the efficiency of gear motors is constantly improving. Newer gear motors are more compact, durable, and efficient than their predecessors. They are also more cost-effective, allowing more manufacturers to adopt them in their robotic systems. The improvements in gear motor technology have resulted in more sophisticated automated systems, that are able to perform a wider range of tasks.

7. Future of Gear Motors in Robotics

The future of the robotics industry is dependent on the advancements of gear motor technology. Gear motors will continue to play an important role in enhancing the efficiency, durability, and accuracy of robotic systems. With the growing demand for automation, there will be a need for more advanced gear motors to meet the application requirements of various industries.

8. Challenges Facing the Gear Motor Industry

One of the challenges facing the gear motor industry is the lack of standardization in gear motor design. This has resulted in compatibility issues between different gear motors. Secondly, the lack of experienced personnel in the repair and maintenance of gear motors has led to increased costs and downtime for maintenance. Finally, environmental concerns such as efficiency and power consumption need to be considered in the design of gear motors.

9. Key Considerations in Selecting Gear Motors for Robotics Applications

When selecting gear motors for robotics applications, there are several key considerations to be made. These include the size and weight of the motor, the level of precision required, the ratio of reduction and the motor's effectiveness in dealing with unexpected events. It is important to consider these factors to ensure that the application is successful and has a long lifespan.

10. Conclusion

The use of gear motors has revolutionized the robotics industry, allowing for more sophisticated automated systems that are more efficient, reliable, and flexible. With the advancements in gear motor technology, new applications are being developed that would have been previously impossible. The gear motor industry will continue to develop to meet the growing demand for automation, offering endless possibilities for the future of robotics.