The Role of Heavy Duty Gear Reducer in Conveyor Systems

Conveyor systems are used extensively in various industries to transport goods from one location to another. The gear reducer plays a crucial role in these systems as it helps to regulate the speed and ensure the smooth movement of the conveyor belt. A heavy-duty gear reducer is required to handle the high demands of heavy-duty applications.

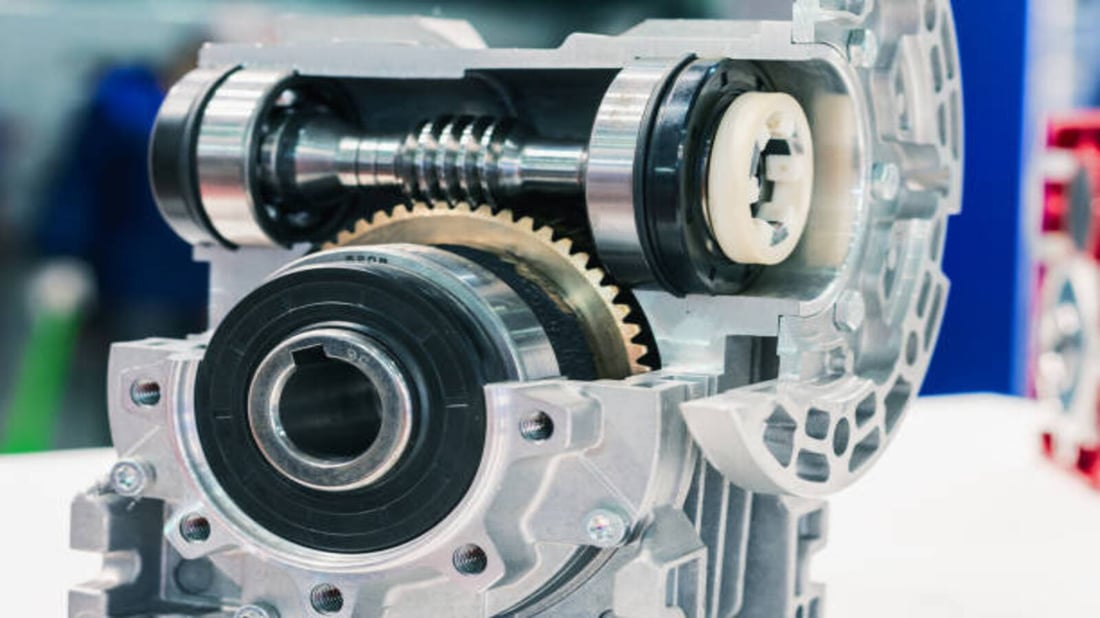

Types of gear reducers

There are several types of gear reducers available in the market to suit different needs. These include worm gear reducers, helical gear reducers, bevel gear reducers, and planetary gear reducers. A heavy-duty gear reducer can be made using any of these types of gears as long as they meet the requirements of the application.

Factors to consider while selecting heavy-duty gear reducer

Selecting a heavy-duty gear reducer is critical for the performance and longevity of the conveyor system. Here are some factors that you should consider while choosing the right gear reducer:

- Load capacity of the conveyor system.

- Speed and torque requirements of the gearbox.

- Environmental factors such as temperature, humidity, and altitude.

- Efficiency and operating costs.

- Noise and vibration levels.

- Space limitations and mounting options.

Benefits of using heavy-duty gear reducers

Heavy-duty gear reducers offer several benefits for conveyor systems. Here are some of the advantages:

- Increased load capacity and higher torque ratings.

- Better heat dissipation and reduced wear and tear.

- Improved efficiency and lower operating costs.

- Reduced noise and vibration levels for a quieter operation.

- Longer service life and reduced maintenance requirements.

- Customization options to suit specific needs.

Applications of heavy-duty gear reducers

Heavy-duty gear reducers are used extensively in various industries that require the movement of heavy loads. Some of the applications include:

- Mining and quarrying.

- Material handling and processing.

- Manufacturing and packaging.

- Construction and transportation.

- Agriculture and forestry.

Tips for maintenance and care of heavy-duty gear reducers

Maintenance and care of heavy-duty gear reducers are critical to ensure their longevity and performance. Here are some tips:

- Follow manufacturer's instructions for lubrication and maintenance.

- Check for leaks, cracks, and other damage regularly.

- Keep the gear reducer clean and free of debris.

- Do not overload the gearbox beyond its capacity.

- Check for alignment and adjust if necessary.

- Replace worn-out parts and bearings as required.

Popular brands of heavy-duty gear reducers

There are several brands of heavy-duty gear reducers available in the market. Some of the popular ones include:

- NORD

- Bonfiglioli

- SEW-EURODRIVE

- Baldor-Dodge

- Sumitomo Drive Technologies

Cost of heavy-duty gear reducers

The cost of heavy-duty gear reducers varies depending on the type, size, and brand. Typically, a heavy-duty gear reducer can cost anywhere from a few hundred to thousands of dollars.

Conclusion

A heavy-duty gear reducer is an essential component of conveyor systems that require the movement of heavy loads. By considering the factors mentioned above, selecting the right gear reducer, and performing regular maintenance and care, you can ensure the longevity and performance of your conveyor system.