Introduction

Industrial equipment and machines require a lot of power, and sometimes it can be challenging to maintain the necessary amount of strength for efficient performance. One of the most effective ways of providing powerful performance while improving efficiency is by using a high torque gear reducer.

What is a High Torque Gear Reducer?

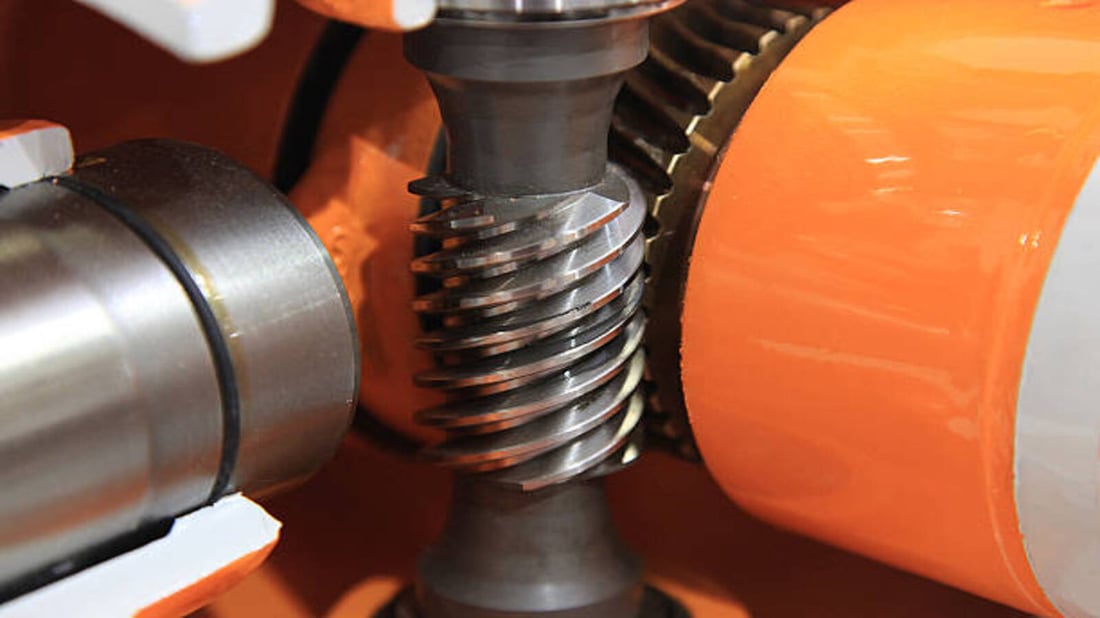

A high torque gear reducer is a device that reduces the input speed of a machine motor and converts it into high output torque. They are specifically designed to handle heavy loads and provide maximum output with minimal input. A significant advantage of these gears is that they can be customized to suit various industrial applications.

Types of High Torque Gear Reducers

There are several types of high torque gear reducers available in the market. Some of the most common types include the planetary, helical, bevel, and worm gear reducer. The type of gear reducer you choose depends on the specific requirements of your industrial application.

Benefits of High Torque Gear Reducers

High torque gear reducers offer various benefits to industries that rely on heavy machinery to perform their operations. The following are some of the advantages of using high torque gear reducers:

- Improved efficiency and performance

- Longer lifespan of machines and equipment

- Better control and precision of machinery

- Noise reduction and smoother operation

- Reduced maintenance costs and downtime

- Increased safety and reliability of machinery

Applications of High Torque Gear Reducers

High torque gear reducers find applications in various industries, including:

- Oil and gas industry

- Mining industry

- Transport and logistics industry

- Material handling industry

- Manufacturing industry

- Automotive industry

Factors to Consider when Choosing a High Torque Gear Reducer

Choosing the right high torque gear reducer depends on several factors, including:

- Load capacity of the machine

- Gear ratio required for the machine

- Environmental conditions such as temperature and humidity

- The level of precision required for the operation

- The location of the gearbox and mounting options

How to Maintain High Torque Gear Reducers

Maintaining high torque gear reducers is essential to ensure their longevity and optimal performance. Here are some tips to help you maintain your gear reducer:

- Always check gear reducer alignment and adjust it regularly

- Ensure that the gear reducer is lubricated correctly

- Regularly inspect the reducer for signs of wear and damage

- Clean the reducer regularly to remove dirt and dust that might damage the gearbox

The Cost of High Torque Gear Reducers

The cost of high torque gear reducers varies depending on the specific type of gearbox and its application. However, the initial cost of installation is often outweighed by the long-term advantages of using high torque gear reducers, such as improved performance, reduced downtime, and increased safety.

Conclusion

High torque gear reducers offer numerous advantages for various industries that rely on heavy machinery to perform their operations. The benefits of using high torque gear reducers include improved efficiency, reduced maintenance costs, increased safety, and longer lifespan of the machinery. By considering the relevant factors and choosing the right high torque gear reducer, you'll be able to optimize your industrial performance and achieve maximum output with minimal input.