custom gear reducer for machinery: An Overview

Custom gear reducers are an essential component of any machinery, as they reduce the revolutions per minute (RPM) of the machinery while increasing its torque. Many industries require custom gear reducers that can optimize the performance of their machinery while adhering to specific parameters. This article will provide you with an informative guide about custom gear reducers for machinery.

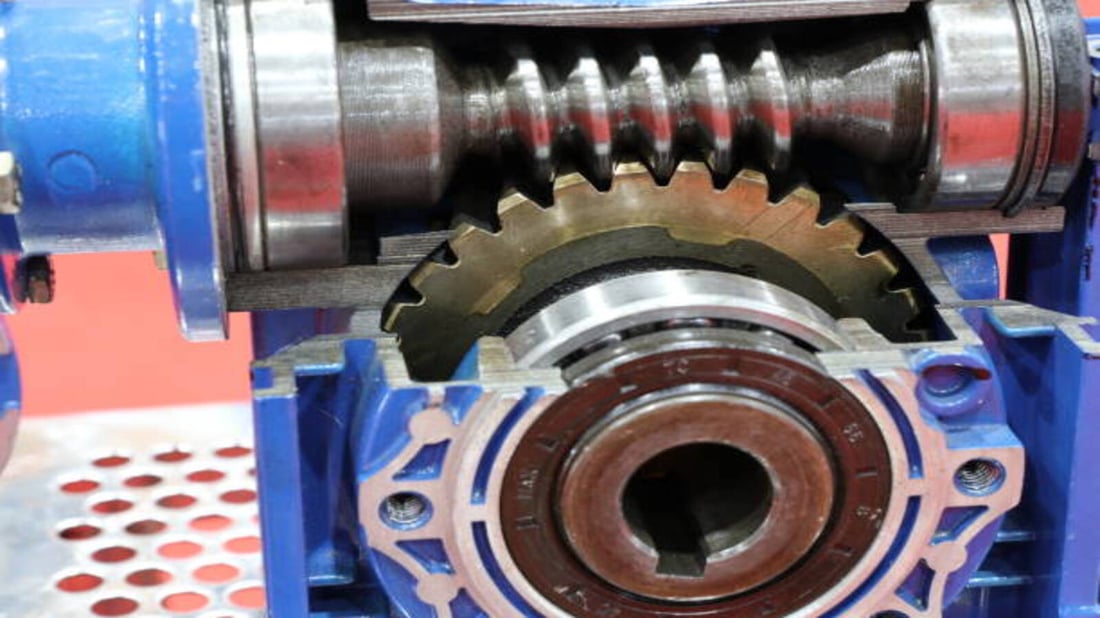

What is a Gear Reducer?

A gear reducer is a mechanical device that is used to reduce the speed of an input shaft/power source by the use of a gear assembly. They are used in various machines to transfer power between two shafts and help to generate large amounts of torque output, usually with a lower input speed. Gear reducers are a vital component of machinery as they protect the motor or engine from damage by decreasing its operating speed.

Benefits of Custom Gear Reducers for Machinery

There are various benefits to utilizing custom gear reducers in your machinery, including:

Increased Efficiency: With a custom gear reducer, you can optimize the equipment's performance that can lead to increased efficiency and reliability.

Better Control: Custom gear reducers offer greater control over the machinery's movement, ensuring smoother and more precise operation.

Cost-Effective: The usage of custom gear reducers can increase the lifespan of machinery, which means you can save money on expensive repairs and replacements.

The Importance of Custom Gear Reducers for Machinery

Custom gear reducers are crucial components for large industrial machinery. They are responsible for balancing speed, thrust, and torque while ensuring smooth machine operation in varying industrial environments. Different industries require customized gear reducers based on their specific machinery requirements that can provide exact power output and speed reduction.

Types of Custom Gear Reducers for Machinery

There are two primary types of custom gear reducers that cater to different kinds of machinery:

Worm Gear Reducers: Worm gear reducers are used in machinery that requires low speed output, high torque, and quiet operation. They are ideal for conveyor systems, wind turbines, and material handling equipment.

Planetary Gear Reducers: Planetary reducers are ideal for applications that need high speed reduction, compact design, and high torque output. They are commonly used in heavy-duty equipment like cranes, excavators, and mining equipment.

The Process of Designing Custom Gear Reducers

The process of designing custom gear reducers involves several steps:

Step 1: Consultation with the client to determine their machinery's requirements and understand the application.

Step 2: Analyze and evaluate the project's requirements, including gear ratios, input/output RPM, and torque.

Step 3: Develop a design and a 3D model to simulate the operation of the gear reducer and ensure it aligns with client requirements.

Step 4: Fabrication of the gear reducer and subsequent testing.

The Advantages of Choosing a Custom Gear Reducer

Fits Specific Requirements: Custom gear reducers are designed to cater to specific machinery requirements and hence offer a higher degree of efficiency and reliability.

Reduces Maintenance: A well-designed custom gear reducer can reduce maintenance costs and downtime, leading to increased productivity.

Increased Life-Span: Custom gear reducers undergo rigorous testing processes and quality checks, ensuring longevity compared to off-the-shelf gear reducers that may not align with the requirements of the machinery.

The Custom Gear Reducer Manufacturing Process

Custom gear reducers for machinery undergo several stages of the manufacturing process, including:

Design: Using computer-aided design (CAD) software, the gear reducer design is created.

Manufacturing: Using computer numerical control (CNC) machines, the components are fabricated for the gear reducer.

Assembly: Skilled technicians assemble and test the gear reducer to ensure it meets the required specifications.

Quality Assurance: Rigorous quality checks and testing are performed to ensure the gear reducer is functioning as per requirements and is durable.

Choosing the Right Custom Gear Reducer Manufacturer for Your Machinery

Choosing the right custom gear reducer manufacturer is crucial for your machinery's performance and longevity. Consider the following factors while selecting a manufacturer:

Experience & Expertise: The manufacturer's experience and technical expertise in designing and fabricating custom gear reducers can significantly impact the final product's quality.

Quality Standards: Ensure that the manufacturer adheres to the industry quality standards and regulations to ensure a high-quality and efficient custom gear reducer.

Customer Support: Choose a manufacturer that provides excellent customer support and prompt responses to your queries and concerns.

The Bottom Line

Custom gear reducers are an integral component of machinery that plays a crucial role in balancing speed, torque, and thrust while ensuring smooth and efficient machine operation. Choosing the right custom gear reducer manufacturer can positively impact your machinery's performance, productivity, and life-span.