The Importance of Compact Gear Reducers for Electric Motors

Electric motors are an essential part of many industrial and commercial processes. The primary purpose of a gear reducer is to decrease the speed of the electric motor while increasing torque. Compact gear reducers for electric motors are specially designed to provide the necessary power and performance needed for specific applications in a smaller, more compact design.

What is a Compact Gear Reducer?

A compact gear reducer is a device that reduces the speed and increases the torque of an electric motor. Its compact design is intended to provide the necessary power while occupying a small space. These devices are commonly used for various industrial applications such as conveyor systems, material handling, and packaging machinery, just to name a few.

Advantages of Compact Gear Reducers

In addition to their small footprint and efficient design, compact gear reducers offer several other advantages. They can increase the life of the electric motor and reduce its operating temperature. They also help to increase efficiency and reduce maintenance costs over time.

Types of Compact Gear Reducers

There are several types of compact gear reducers available for electric motors. Some of the most common include planetary, helical-bevel, and worm gear reducers. Each type has its own unique advantages and disadvantages depending on the specific application requirements.

Planetary Gear Reducers

Planetary gear reducers are known for their high efficiency, accuracy, and low backlash. They are typically more compact and can deliver a higher torque density compared to other types of gear reducers. These reducers are commonly used in high-precision applications such as robotics and automation systems.

Helical-Bevel Gear Reducers

Helical-bevel gear reducers are known for their quiet operation and high reliability. They are ideal for handling high shock loads and heavy-duty applications. They can provide higher torque and efficiency compared to other types of reducers, making them popular in harsh working conditions such as paper mills and steel plants.

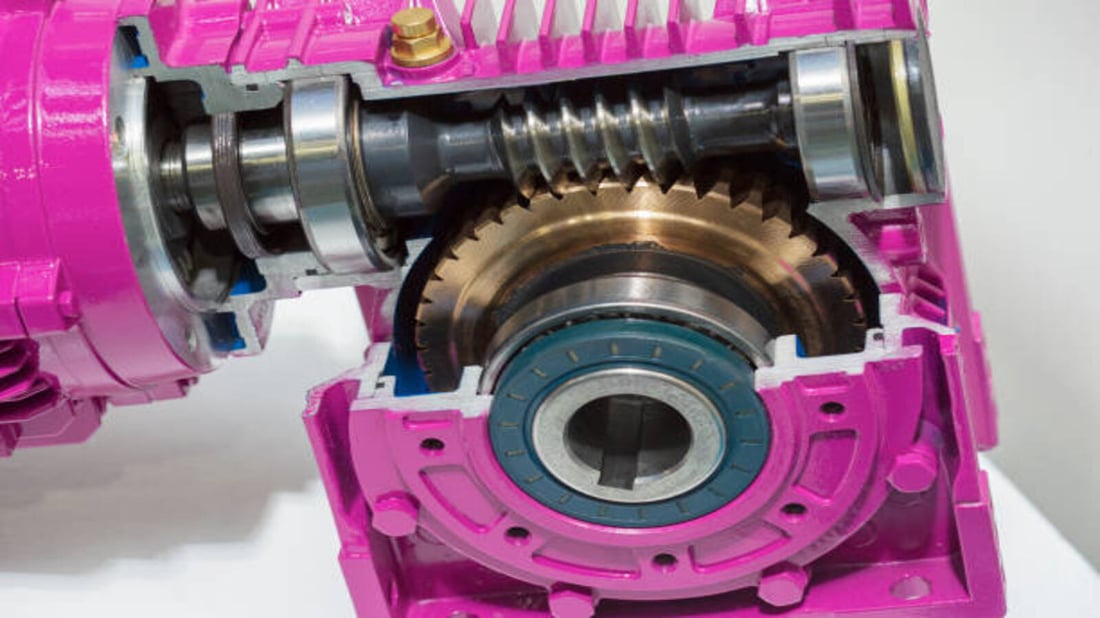

Worm Gear Reducers

Worm gear reducers are known for their durability and ability to handle shock loads. They offer a compact design and can provide a high reduction ratio. These reducers are often used in low-speed and high-torque applications such as conveyors, agitators, and mixers.

How to Choose the Right Compact Gear Reducer for Your Application

Choosing the right compact gear reducer for your application can be a daunting task. It's essential to consider several factors such as the speed reduction ratio, torque requirements, and application environment. Consulting with an experienced engineer can help ensure that you select the best gear reducer for your needs.

Installation Tips for Compact Gear Reducers

Proper installation of compact gear reducers is essential for optimal performance and longevity. It's essential to follow the manufacturer's guidelines and use the appropriate tools and techniques during installation. Regular maintenance checks of your gear reducer can also help extend its life and prevent downtime.

Conclusion

Compact gear reducers for electric motors are an essential part of many industrial applications. By reducing the speed of the electric motor and increasing torque, compact gear reducers can increase the efficiency and lifespan of electric motors while reducing operating costs. When selecting and installing a compact gear reducer, it's essential to choose the right type for your application and follow proper installation and maintenance procedures.