Introduction

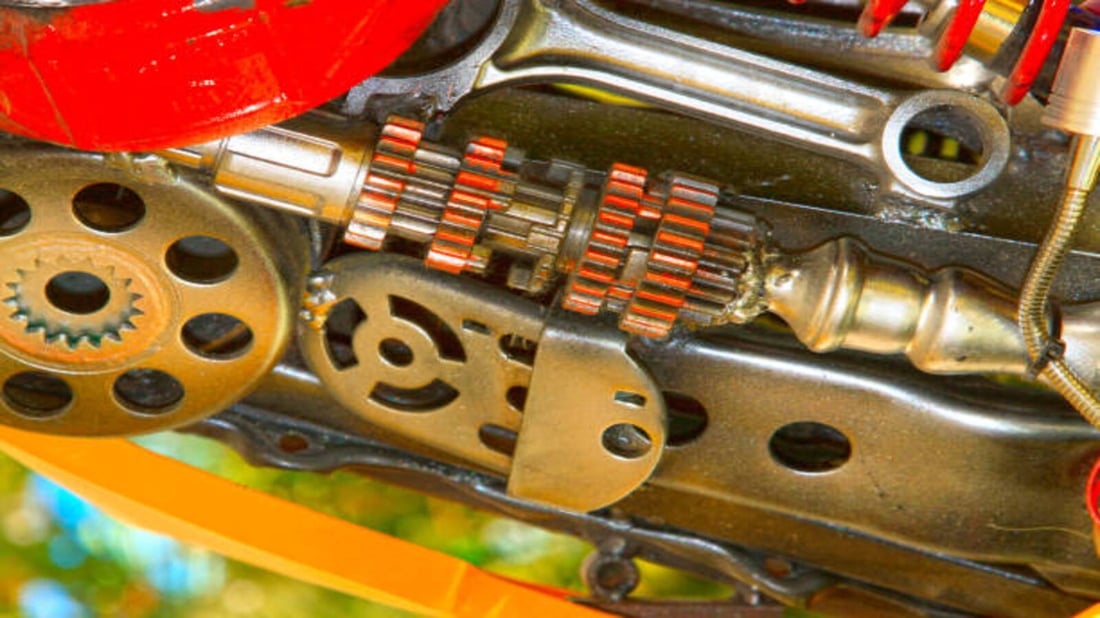

Gearboxes are an essential component of any mechanical system that requires torque variation or a change in rotational speed. They can be found in various machines, including cars, industrial machinery, and boats. However, like any mechanical part, gearboxes are subject to wear and tear and can break down without proper maintenance. In this article, we will discuss the most Common Gearbox Failures and How to Prevent Them.

Overheating of Gearboxes

Gearboxes can overheat due to a lack of adequate lubrication, which can lead to the breakdown of gearbox components such as the bearings. To prevent overheating, ensure the gearbox is filled with the correct oil level and that the oil is suitable for the gearbox. Ensure the gearbox oil is changed regularly to prevent lubrication breakdown due to heat.

Gear Wear and Tear

Gears are susceptible to wear and tear; this becomes more evident when there is repeated stress in a small area, leading to gear teeth breaking, crack initiation and wear. One of the most common causes of wear and tear is shock loading, which puts added strain on the gearbox. To prevent gear wear, make sure the gearbox is not overloaded or exposed to heavy shock loads. Regular inspections should be carried out to ensure gears are not damaged.

Contamination of Gearbox Oil

Gearboxes are typically prone to contamination from dirt, water and dust, leading to gearbox failure. Once contaminated, the oil's viscosity significantly reduces, and it can cause abrasive wear and other metal fatigue issues. Regular oil changes and the use of suitable gearbox oil can reduce the chances of oil contamination. Using oil filters can also help to keep oil free from contaminants.

Seal Failure

Seal failure is another common cause of gearbox failure. Seals are essential for preventing oil from leaking out or contaminants from entering the gearbox. Once a seal begins to fail, the gearbox oil can become contaminated, reducing the oil's viscosity, which leading to gearbox failure. Regular inspections should be carried out to ensure that all seals are correctly positioned and operational.

Bearing Failure

Bearing failure is a common gearbox failure caused by the lack of lubrication or inadequate lubrication leading to metal-to-metal contact. Lack of adequate lubrication can cause a lack of viscosity in the oil, reducing the oil film thickness, leading to bearing damage. Regular inspections and lubrication are necessary to prevent bearing failure.

Alignment Issues

Shaft misalignment can cause significant problems for gearboxes, leading to increased loads on the bearings, shafts and gears. This can lead to these components failing much faster than anticipated. Proper alignment of shafts is necessary to avoid any issues with the gearbox.

Shim Migration

Shim migration occurs when the shims used for gearbox set up are moved under load or upon exposure to heat. This results in poor gearbox performance or eventually leads to complete gearbox failure. To prevent shim migration, use correct shim materials with appropriate thickness and surface finish. Fasteners and locking mechanisms should also be adequate to keep the shims in place.

Corrosion and Rust

Gearboxes, like any metal component, can rust or corrode over time, leading to concrete gearbox failure. Often rust or corrosion is caused by inadequate storage to protect the gearbox against the elements. To prevent corrosion and rust, the gearbox should be painted and adequately stored in a dry environment when not in use.

Electrical Failures

Electrical failures can be caused by a variety of reasons, including the build-up of conductive dust, moisture accumulation and improper grounding. Electrically charged gearboxes can lead to fire hazards and endanger the operator. To prevent electrical failures, ensure that the gearbox has adequate grounding, is kept clean and dry and is regularly inspected for any electrical faults.

Conclusion

Gearboxes are important components in many mechanical systems, and their failure can be catastrophic. By understanding common gearbox failures and taking measures to prevent them, operators can enjoy optimal gearbox performance and longevity. Regular inspections and maintenance are essential to prevent gearbox failure and avoid costly replacement expenses.