Understanding Chain Sprocket Basics

A chain sprocket is a simple yet highly effective piece of mechanical equipment that is utilized in a variety of applications, including motorcycles, bicycles, conveyors, agricultural machinery, and many others. The chain sprocket works in tandem with the chain to transfer rotational motion from one device to another. In this article, we will delve into the basics of chain sprockets, their design, working principle, and usage.

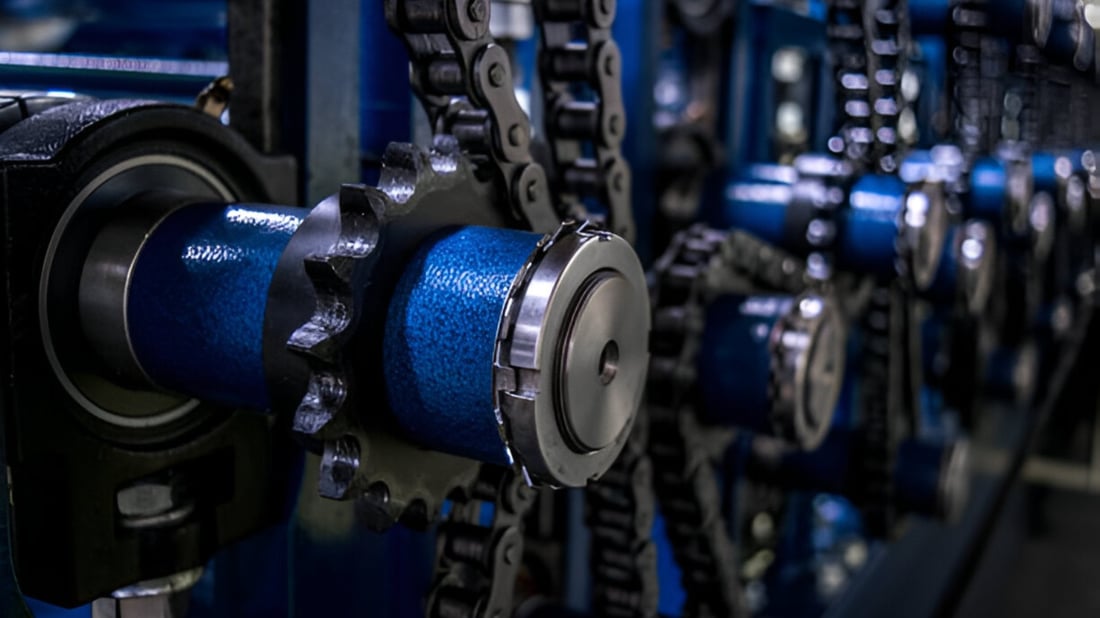

What are Chain Sprockets?

A chain sprocket is a toothed wheel that works in conjunction with a chain to transfer power or motion from one mechanical device to another. Sprockets are made of a variety of materials, including steel, aluminum, and plastic, and come in a variety of sizes and shapes.

The Components of Chain Sprockets

Chain sprockets are made up of several components, each of which plays a critical role in their functionality. These include:

- The outer diameter: The overall diameter of the sprocket that determines the overall length of the chain.

- The pitch diameter: The diameter of the sprocket measured at the point where the chain engages it.

- Teeth: The number of teeth on the sprocket that engage with the chain and dictate the gear ratio.

- Hub: The center of the sprocket that is mounted onto a shaft.

The Working Principle of Chain Sprockets

The working principle of chain sprockets is simple yet effective; the sprocket engages with the teeth of a chain to transfer power or motion from one mechanical device to another. The chain wraps around the sprocket and engages with its teeth, which rotate as the shaft turns. The rotational motion is then transferred through the chain to another sprocket or mechanical device.

Types of Chain Sprockets

There are several types of chain sprockets that are used in various applications. These include:

- Standard sprockets: These are the most common types of sprockets and are used in a wide variety of applications.

- Taper-lock sprockets: These sprockets have a tapered bore that allows them to be easily mounted onto a shaft without the need for a key.

- Idler sprockets: These sprockets are used to guide the chain in applications where slack may occur.

- Double sprockets: These sprockets have two sets of teeth, each engaging with a separate chain.

How to Choose the Right Chain Sprocket

Choosing the right chain sprocket for your application requires careful consideration of several factors, including:

- The pitch of the chain and sprocket: These must match to ensure proper engagement and transfer of motion.

- The chain width: This must be compatible with the sprocket teeth width to ensure proper engagement.

- The number of teeth: This determines the gear ratio, which should be selected based on the speed and torque requirements of your application.

Maintenance of Chain Sprockets

Proper maintenance of chain sprockets is essential to ensure their longevity and optimal functionality. This includes:

- Regular cleaning to remove debris and lubrication to reduce friction.

- Inspection for wear and damage, particularly to the teeth and bore.

- Replacement of any worn or damaged components to avoid failure and potentially catastrophic consequences.

Advantages of Chain Sprockets

The advantages of using chain sprockets include:

- High efficiency transmission of power or motion due to minimal slip.

- Variable gear ratios can be achieved by using sprockets of different sizes.

- Minimal maintenance requirements when properly cared for.

- Reliable and time-tested technology that has proven effectiveness in a vast array of applications.

Applications of Chain Sprockets

Chain sprockets are widely used in a variety of industries, including:

- Transportation: Bicycles, motorcycles, and cars utilize chain sprockets to transfer power from the engine to the wheels.

- Manufacturing: Conveyors, packaging machines, and assembly lines all make use of chain sprockets to transfer motion or power between devices.

- Agriculture: Tractors, combines, and other farm machinery rely on chain sprockets to transfer power and motion from the engine to various implements.

Conclusion

Chain sprockets are a fundamental piece of mechanical equipment that has been used for over a century to transfer motion and power between mechanical devices. Understanding the basics of their design, working principle, and usage will allow you to make informed decisions when selecting, maintaining, and utilizing chain sprockets in your applications.